Mechanical Properties of Bamboo

What are the mechanical properties of bamboo? It is propably one of the most frequently asked questions among European or American architects, engineers and builders. Such information is easily found and available for wood, steel, concrete or even engineered bamboo products such as flooring and panelling, but this is not the case for bamboo poles. Why?

“The mechanical properties of bamboo are often twice to three times higher than those of conventional timbers. However, legal uncertainties surrounding universal regulations and standards are preventing a bamboo boom in many parts of the world.”

Bamboo consists of many different species and each of those bamboo species have different structural and mechanical properties just as trees; Teak, Oak or Balsa wood don't have the same properties either. Furthermore, one single bamboo species can show very different test results depending on the age and moisture content of the tested bamboo pole, its origin (soil, altitude, climate conditions), and the part of the stem that is tested (bottom, middle or top part of the "tree").

Another important reason for the lack of information is the fact that bamboo poles as a building material are still relatively unknown in Europe or North America (partly because construction grade timer bamboos primary grow in tropical countries). It is only in the last 30-35 years that mechanical properties of bamboo have been scientifically tested.

Why are Mechanical Properties Important?

Most countries have no standard building codes for bamboo which makes it difficult for those who wish to use the material in construction. There is a kind of legal uncertainty surrounding the determination of certain bamboo properties such as fire resistance, strength properties, durability, and so on, which implies that there is an urgent need for regulations and standards.

Bamboo Bending Test | Courtesy: Pablo Acevedo

Strength properties for bamboo have already been tested by universities around the world and present outstanding results which are in many cases much superior to conventional building materials. However, building code standards require more than the strength properties of a material alone, other properties to consider are:

Durability

Fire Safety

Environment Impact

User Safety

Energy Efficiency

Fire resistance and durability are areas that still need further research before a standard building code can be appointed to bamboo. Nevertheless, important progress has been made by introducing an international ISO 22157 standard for the mechanical properties of bamboo.

The International Organization for Standardization (ISO)

The International Organization for Standardization, known as ISO has drawn up its own standard for determining the mechanical properties of bamboo in 2004. This is a first and very important step to get bamboo poles approved as a building material worldwide.

The ISO 22157 standard describes how bending strength, compression, tension, shear and durability must be determined. For those interested, the guidelines can be found here.

In this article we present several test results from various sources and on various bamboo species. It is importnat to note that not all tests were conducted according the ISO 22157 standard but it does give a general idea of the mechanical properties of bamboo.

Compressive Strength

There are two types of compressive strength that need to be tested according to the ISO 22157 standard; compressive strength parallel to grain and compressive strength perpendicular to grain. Strangely enough ISO 22157 guidelines only describe the testing methodology for compressive strength parallel to grain but do not provide a methodology for compressive strength perpendicular to grain. For that reason we will only discuss the former.

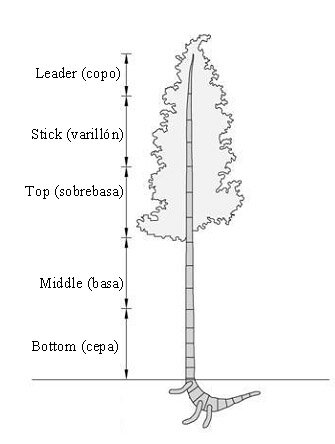

Parts of the bamboo stem

Because of the natural shape of a bamboo "tree", 3 different parts of the stem need to be tested: the bottom, middle and top part. This is necessary because a bamboo stem does not have a continuous cross-section and there are differences in structural properties between the lower part, which has a larger diameter, and the upper part, which has a smaller diameter.

The test samples cannot contain a node because the results of these samples would not provide accurate results as the nodes are the strongest areas in a bamboo stem. Therefore, test samples are taken from the section between two nodes (internodes), as this is the weakest part of a bamboo pole.

For construction purposes only the bottom, middle and top part can be used as columns or beams. The 'leader' and 'stick' part of the bamboo culm are not considdered useful in construction because of their small diameter.

Compressive Strength of Guadua angustifolia

Mechanical properties of the species Guadua angustifolia were tested according to ISO 22157 standards at the Los Andes University in Bogota, Colombia in 2010. Three samples of 2-3-4 and 5 year old Guadua bamboo were used to determine the influence of age on its mechanical properties.

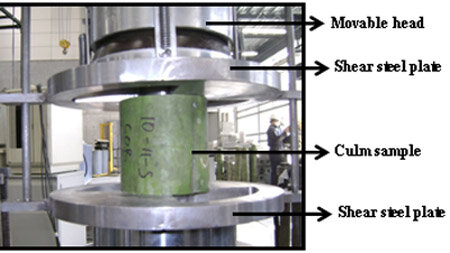

Compressive Test Setup

Steel plate with wedges

The average moisture content of the bamboo samples (which is an important parameter) were 59.3%, 56.5%, 56.7% and 65.2%, respectively. The average outer diameter of the bottom part was 13 cm, of the middle part 12 cm, and 10 cm for the top portion.

| Compressive Strength of Guadua angustifolia | |||||

|---|---|---|---|---|---|

| Age of Bamboo Stems (Years) | |||||

| 2 | 3 | 4 | 5 | ||

| Bottom | E (N/mm2) | 15500 | 16500 | 17400 | 15200 |

| σ (N/mm2) | 39.9 | 38.1 | 37.6 | 32.1 | |

| Middle | E (N/mm2) | 14900 | 18000 | 16800 | 16500 |

| σ (N/mm2) | 27.2 | 42.1 | 41.5 | 34.7 | |

| Top | E (N/mm2) | 20000 | 17000 | 17500 | 18200 |

| σ (N/mm2) | 20.4 | 42.6 | 42.1 | 39.0 | |

The maximum compressive strength for Guadua angustifolia was observed in 3-4 year old culms with a average of 40 N/mm2 (in a green state). The compressive strength from 5 years old Guadua decreased about 16% compared to the strength of 3- 4 year old Guadua.

Comparing Compressive Strength of Various Bamboo Species

The following table provides an overview of the compressive strength of various bamboo species. It is important to note that not all testing results comply with the ISO 22157 standard. The values shown in the table are average values, so they do not mention differences in vertical direction or age.

| Compressive Strength of Various Bamboo Species | |||||

|---|---|---|---|---|---|

| Species | σ (N/mm2) | E (N/mm2) |

ρ (kg/m3) | M.C. (%) | Source |

| Bambusa balcooa | 39.4 - 50.6 | - | - | green | Kabir et al |

| 51 - 57.3 | - | - | air dry | ||

| 69 | - | 820 | 8.5 | Naik | |

| Bambusa bambos | 61 | - | 710 | 9.5 | |

| 39.1 - 47 | - | - | - | Gnanaharan | |

| Bambusa nutans | 75 | - | 890 | 8 | Naik |

| 46 | - | - | 87 | Sekhar | |

| 85 | - | - | 12 | ||

| 44.7 | - | - | 88.3 | Inbar | |

| 47.9 | - | - | 14 | ||

| Bambusa pervariabilis | 45.8 | 15200 | - | - | Yuen |

| 79 | 10300 | - | < 5 | Yu & Chung | |

| 35 | 6800 | - | > 20 | ||

| Bambusa polymorpha | 32.1 | - | - | 95.1 | Inbar |

| Bambusa spinosa | 57 | - | - | - | Espinosa |

| Bambusa tulda | 40.7 | - | - | 73.6 | Inbar |

| 68 | - | - | 11.9 | ||

| 79 | - | 910 | 8.6 | Naik | |

| Dendrocalamus giganteus | 70 | - | 740 | 8 | |

| Dendrocalamus hamiltonii | 70 | - | 590 | 8.5 | |

| Dendrocalamus membranaceus | 40.5 | - | - | 102 | Inbar |

| Gigantochloa apus | 21.7 - 26.5 | - | - | 54.3 | |

| 27.3 - 48.6 | - | - | 15.1 | ||

| Gigantochloa atroviolacea | 23.8 | - | - | 54 | |

| 35.7 | - | - | 15 | ||

| Gigantochloa atter | 24.8 - 28 | - | - | 72.3 | Prawirohatmodjo |

| 31 - 32.9 | - | - | 14.4 | ||

| Gigantochloa macrostachya | 71 | - | 960 | 8 | Naik |

| Guadua angustifolia | 42 | 27000 | - | - | Sotela |

| 63.6 | - | - | - | Rwth Aachen | |

| 86.3 | - | - | - | ||

| 62 - 93 | - | - | - | DB Magazine | |

| 56 | 18400 | - | 15 | Eicher | |

| 63.3 | 15190 | - | - | Laroque | |

| 28 | 15000 | - | - | Trujillo | |

| 56.2 | 17860 | - | - | Caori | |

| 38 | 14500 | - | - | Uribe | |

| Melocanna baccifera | 69.9 | - | - | 12.8 | Inbar |

| Phyllostachys bambusoides | 51 | - | - | - | Glenn |

| 63 | - | 730 | 8 | Naik | |

| 44 | - | - | 64 | Limaye | |

| 40 | - | - | 61 | ||

| 71 | - | - | 9 | ||

| 74 | - | - | 9 | ||

| 54 | - | - | 12 | Sekhar | |

| Phyllostachys edulis | 44.6 | 11300 | - | - | Yen |

| 67 | - | - | 50 - 99 | Ota | |

| 71 | - | - | 14 - 17 | ||

| 108 | - | - | 5 - 7 | ||

| 147 | - | - | 0.1 - 0.3 | ||

| 117 | 9400 | - | < 5 | Yu & Chung | |

| 44 | 6400 | - | > 30 | ||

| 60.3 | - | 603 | 12.5 | KaHo | |

| Phyllostachys praecox | 79.3 | - | 827 | 28.5 | |

| Thyrsostachys oliveri | 46.9 | - | - | 53 | Inbar |

| 58 | - | - | 7.8 | ||

Conclusion:

The compressive strength of bamboo is roughly situated between 40 and 80 N/mm2 which is twice to four times the value of most timber species. The difference in results can be explained by the different test methods and samples that were used. However, it is clear that age and moisture content of bamboo samples have a significant influence on the compressive strength of bamboo. Bamboo with low moisture content has a higher compressive strength than bamboo with high moisture content.

Tensile Strength

The maximum tensile strength of bamboo is determined by testing the fibers (bamboo strips) and not on entire culm samples. As with compressive strength, the ISO 22157 standard does provide guidelines for tensile strength parallel to grain but not for tensile strength perpendicular to grain.

To test bamboo's tensile strength, 3 trips are used from the lower part, the middle part and the upper part of the entire bamboo stem. Each strip is between 10-20 mm wide, has the thickness of the bamboo culm, and is 100 mm long. Moisture content of each sample must be determined and samples must have a node. As the fiber direction of the node is opposite to the fiber direction of the internode, the node is here considered the weakest point of the stem (when testing compressive strength it is the other way around).

The following table shows the tensile strength of the most popular bamboo species used in structural applications.

| Tensile Strength of Various Bamboo Species | |||||

|---|---|---|---|---|---|

| Species | σ (N/mm2) | E (N/mm2) |

ρ (kg/m3) | M.C. (%) | Source |

| Bambusa balcooa | 164 | - | 820 | 8.5 | Naik |

| Bambusa bambos | 121 | - | 710 | 9.5 | |

| Bambusa nutans | 208 | - | 890 | 8 | |

| Bambusa tulda | 207 | - | 910 | 8.6 | |

| Dendrocalamus giganteus | 177 | - | 740 | 8 | |

| Dendrocalamus hamiltonii | 177 | - | 590 | 8.5 | |

| Dendrocalamus strictus | 160 | 17500 | - | 11.4 | Janssen |

| Gigantochloa apus | 294.1 | - | - | 54.3 | Prawirohatmodjo |

| 298.9 | - | - | 15.1 | ||

| Gigantochloa atroviolacea | 237.4 | - | - | 54 | |

| 237.4 | - | - | 15 | ||

| Gigantochloa atter | 273 - 299.8 | - | - | 72.3 | |

| 247 - 332 | - | - | 14.4 | ||

| Gigantochloa macrostachya | 168 | - | 960 | 8 | Naik |

| Gigantochloa pseudoarundinacea | 177.9 | 27631 | 690 | - | Arce-Villalobos |

| 149.4 | 19643 | 629 | - | ||

| Guadua angustifolia | 148 - 384 | - | - | - | DB Magazine |

| 191.9 | - | - | - | Lopez | |

| 90 | - | - | - | Trujillo | |

| 162.7 | 17900 - 24100 | - | - | Laroque | |

| Phyllostachys bambusoides | 140 | - | 730 | 8 | Naik |

| 120 | - | - | 12 | Janssen | |

| Phyllostachys edulis | 115 - 309 | 8987 - 27397 | 553 - 1006 | 4.9 - 7.8 | Yu |

Conclusion:

The average tensile strength of bamboo is situated roughly around 160 N/mm2 which is often 3 times higher than most conventional construction grade timbers.

Shear Strength

The maximum shear stress for bamboo is an important factor to design appropriate joinery systems and connections. Shear stresses can occur in two ways, parallel to the grain and perpendicular to grain. Again, ISO 22157 standards only provides guidelines for measuring shear stress parallel to grain.

Three samples from the lower, middle and upper part of the bamboo stem are tested. The difference this time is that half of the test samples should have a node and the other half should not have a node.

Each sample is carefully measured before testing. The height of the test piece and the thickness of the culm are measured at the 4 zones where shear will occur. This is important because a bamboo culm isn't uniform in thickness and the sample cross cuts may not be perfectly executed.

Shear Strength of Guadua angustifolia

In the same way they tested the compressive strength of Guadua angustifolia, the Los Andes University in Bogota also investigated the same Guadua samples on shear stress according to the ISO 22157 standard.

A few pictures of the test setup are shown below:

Shear Test Setup

Shear Steel Plates

The shear strength of Guadua angustifolia according to age and location of the test sample is shown in the following table:

| Shear Strength of Guadua angustifolia | |||||

|---|---|---|---|---|---|

| Age of Bamboo Stems (Years) | |||||

| 2 | 3 | 4 | 5 | ||

| Bottom | τ (N/mm2) | 7.2 | 7.4 | 7.5 | 6.6 |

| Middle | τ (N/mm2) | 7.5 | 8.2 | 8.0 | 7.4 |

| Top | τ (N/mm2) | 7.2 | 8.1 | 7.6 | 8.0 |

Similar to the compressive strength results, Guadua offers the most resistance to shear in the middle and upper part of a 3-4 year old stem sample. The average shear strength of Guadua angustifolia is 8 N/mm2 (at a moisture content of approximately 56.6%).

Comparing Shear Strength of Various Bamboo Species

The shear strength of various bamboo species is listed in the table below. Again we can not confirm that all testing was performed according to ISO 22157 standards, but it does provide a general insight.

| Shear Strength of Various Bamboo Species | ||||

|---|---|---|---|---|

| Species | τ (N/mm2) | ρ (kg/m3) | M.C. (%) | Source |

| Bambusa balcooa | 11.9 | 820 | 8.5 | Naik |

| Bambusa bambos | 9.9 | 710 | 9.5 | |

| Bambusa nutans | 10.5 | 890 | 8 | |

| 6.7 | - | - | Sekhar | |

| 7.7 | - | - | ||

| 7.9 | - | - | ||

| 9.8 | - | - | ||

| 7.9 | - | - | ||

| Bambusa pervariabilis | 10.3 | - | 12 | Janssen |

| 8.7 | - | 12 | ||

| Bambusa tulda | 9.9 | 910 | 8.6 | Naik |

| Dendrocalamus giganteus | 10.6 | 740 | 8 | |

| Dendrocalamus hamiltonii | 6.7 | 590 | 8.5 | |

| Gigantochloa apus | 6 - 7.7 | 54.3 | Prawirohatmodjo | |

| 7.5 - 7.7 | 15.1 | |||

| Gigantochloa atroviolacea | 6.4 - 11.3 | 54 | ||

| 7.9 - 9.5 | 15 | |||

| Gigantochloa atter | 5.8 - 10.8 | 72.3 | ||

| 9.5 - 10.8 | 14.4 | |||

| Gigantochloa macrostachya | 9.6 | 960 | 8.1 | Naik |

| Guadua angustifolia | 4 - 5 | - | - | Trujillo |

| 16.7 | - | - | Rwth Aachen | |

| Phyllostachys bambusoides | 8.7 | 730 | 8 | Naik |

| Phyllostachys edulis | 8.9 - 12.5 | - | 12.5 | Ota |

| 8.9 | - | green | Dickerson | |

Conclusion:

Shear stress parallel to grain is approximately 10 times lower than compressive strength and even 20 times lower than the tensile strength of the same bamboo species. Still, the shear strength of bamboo is often twice the value of popular timber species.

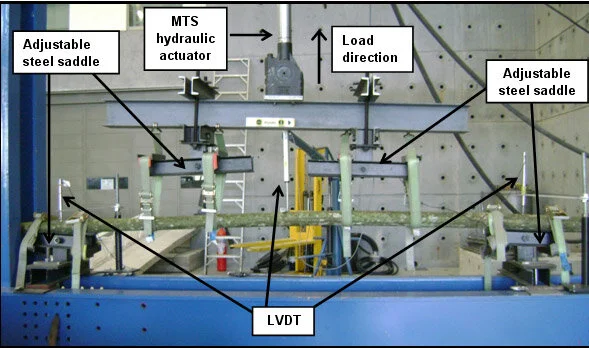

Bending Strength

Bending strength has a direct influence on the behavior of a structure, it is necessary to predict the deflection of each element of a structure before it is build. The most commonly used method for determining the deflection of a beam or column is the four-point bending test.

Bending Strength of Guadua angustifolia

The four-point bending test, as required by the ISO 22157 standard was conducted at the Los Andes University in Colombia. The testing was performed on the same bamboo poles as in the test for determining compressive and shear strength.

Bending Test Setup

During this four-point bending test, the modulus of elasticity (MOE) and modulus of rupture (MOR) are examined. The results of these test are shown in the following table.

| Bending Strength of Guadua angustifolia | |||||

|---|---|---|---|---|---|

| Age of Bamboo Stems (Years) | |||||

| 2 | 3 | 4 | 5 | ||

| Bottom | MOE (N/mm2) | 16900 | 16700 | 17000 | 18000 |

| MOR (N/mm2) | 93.6 | 88.8 | 86.9 | 86.3 | |

| Middle | MOE (N/mm2) | 17700 | 15800 | 17000 | 18700 |

| MOR (N/mm2) | 84.7 | 91.6 | 103.7 | 86.9 | |

| Top | MOE (N/mm2) | 16100 | 19400 | 18300 | 15500 |

| MOR (N/mm2) | 107.3 | 97.8 | 103.8 | 107.0 | |

The modulus of elasticity for 5 year old Guadua angustifolia poles is the greatest in the bottom and middle part of the stem. For the top part of the stem the highest modulus of elasticity is measured when they are 3-4 years old. The modulus of rupture is the highest in the top part of the stem, overall it can be concluded that Guadua angustifolia has an average bending strength of 100 N/mm2.

Comparing Bending Strength of Various Bamboo Species

The following table is a summary for the bending strength of several bamboo species. The results may show slight deviations because not all of the data was acquired by the four-point bending test as defined in the ISO 22157 norm. Nevertheless, they do give a general idea for the bending strength of different bamboo species.

| Bending Strength of Various Bamboo Species | |||||

|---|---|---|---|---|---|

| Species | MOR (N/mm2) | MOE (N/mm2) |

ρ (kg/m3) | M.C. (%) | Source |

| Bambusa balcooa | 62.4 - 85 | 7200 - 10300 | - | green | Kabir et al |

| 69.6 - 92.6 | 9300 - 12700 | - | air dry | ||

| 151 | 13603 | 820 | 8.5 | Naik | |

| Bambusa bambos | 143 | 14116 | 710 | 9.5 | |

| 35 - 39.3 | 1500 - 4400 | - | - | Gnanaharan | |

| Bambusa nutans | 52.9 | 6700 | - | 88.3 | Inbar |

| 52.4 | 10700 | - | 14 | ||

| 56 - 79 | 8800 - 10000 | - | green | Sekhar | |

| 76 - 100 | 9300 - 16000 | - | air dry | ||

| 216 | 20890 | 890 | 8 | Naik | |

| Bambusa pervariabilis | 37 | 16400 | - | > 20 | Yu & Chung |

| 80 | 22000 | - | < 5 | ||

| Bambusa polymorpha | 28.3 | 3100 | - | 95.1 | Inbar |

| 35.5 | 4100 | - | 13.9 | ||

| Bambusa spinosa | 55.4 | - | - | air dry | Espinosa |

| 44.9 | - | - | air dry | ||

| 55 | 10300 | - | air dry | Teodoro | |

| Bambusa tulda | 51.1 | 800 | - | 73.6 | Inbar |

| 66.7 | 1000 | - | 11.9 | ||

| 194 | 18611 | 910 | 8.6 | Naik | |

| Dendrocalamus giganteus | 193 | 16373 | 740 | 8 | |

| Dendrocalamus hamiltonii | 89 | 9629 | 590 | 8.5 | |

| Dendrocalamus membranaceus | 26.3 | 2400 | - | 102 | Inbar |

| 37.8 | 3700 | - | 7 | ||

| Dendrocalamus strictus | 68 | 12000 | - | green | Limaye |

| 107 | 15600 | - | air dry | ||

| 92 - 97 | 13700 - 16000 | - | 12 | ||

| 105 | 13200 | - | 61 | ||

| 98.5 | 13600 | - | 55 | ||

| Gigantochloa apus | 102 | - | - | 54.3 | Prawirohatmodjo |

| 87.5 | - | - | 15.1 | ||

| Gigantochloa atroviolacea | 92.3 | - | - | 54 | |

| 94.1 | - | - | 15 | ||

| Gigantochloa atter | 87.9 - 108.1 | - | - | 72.3 | |

| 117.7 - 127.7 | - | - | 14.4 | ||

| Gigantochloa macrostachya | 154 | 14226 | 960 | 8 | Naik |

| Guadua angustifolia | 53.5 | 7400 | - | - | Gnanaharan |

| 144.8 | 17600 | - | - | Janssen | |

| 74 - 100 | 17900 | - | 15 | Eicher | |

| 46 | 11800 | - | - | Trujillo | |

| 82 | 12500 | 600 | 12.6 | De Vos | |

| 72.6 | 17608 | 640 | 11.4 | Inbar | |

| Melocanna baccifera | 57.6 | 12900 | - | 12.8 | |

| Phyllostachys edulis | 55 | 9600 | - | > 30 | Yu & Chung |

| 51 | 13200 | - | < 5 | ||

| 83 | 8400 | 530 | 10.3 | De Vos | |

| Thyrsostachys oliveri | 61.9 | 9700 | - | 53 | Inbar |

| 90 | 12200 | - | 7.8 | ||

Conclusion:

The bending strength of most bamboo species varies between 50 and 150 N/mm2 and is on average twice as strong as most conventional structural timbers. Variations within the same species are caused by the different test methods, sample quality and moisture content of the tested bamboo.

Sources: